12 To 6 Volt Battery Conversion

A re-VOLTing experience

The problem of finding a battery to

fit many early motorcycles can be a tough one. A very limited number of

6 volt motorcycle batteries are being manufactured today. The dimensions

of those that are rarely fit the dimension of an antique motorcycle’s battery

box. The result is that you usually resort to running a smaller (sometimes

much smaller) than normal battery just to have something in the battery

box. Running a smaller battery than normal creates two problems. First,

because of the lack of battery amp/hour capacity, your lights will not

be as bright as they should or will grow dim sooner than normal. Secondly,

your generator is much more likely to overcharge the little battery, severely

reducing its life expectancy.

An easy and economical way to make

a 6 volt battery that will come very close to filling your battery box,

is to convert a 12 volt battery. Dozens of different sizes are available

from your local motorcycle or power equipment dealer. All you need to do

is select a suitable donor. The resulting 6 volt battery, while extremely

functional, wins no awards for original appearance. For this reason the

conversion is best suited to machines that use an enclosed battery box.

It can also be used with a replica battery shell or hollowed out original

battery with a little ingenuity.

How are we going to do this you ask?

Well its not alchemy, but it’s almost as valuable as turning lead into

gold. Essentially, you’ll be sawing a perfectly good, brand new 12 volt

lead/acid battery in half to make a 6 volt! All motorcycle type batteries

are divided into cells. Each cell produces approximately 2.1 volts. So

actually a 12 volt battery produces about 12.6 volts - cut in half you’ll

end up with a 6.3 volt battery.

A few words of caution first. Only

use a new battery that has never had acid in it. Battery (sulfuric) acid

is nasty stuff that can cause serious injury to you and your motorcycle.

Use only a lead/acid battery, not use a “gel” or any other super-duper

modern type battery. Whenever you’re handling acid, always wear approved

safety goggles, rubber gloves and protective clothing. Work in a well ventilated

space, preferably outdoors.

The first thing you need to do is measure

the dimensions of your battery box or case. You will be selecting

Donor battery showing approximate location of cut

You will want a new 12 volt battery

that is almost as tall as the box (leaving a little room for a battery

pad on the bottom and connections on top) and width to just fit inside

the box. The battery’s length should be just a little less than twice the

length of the box or shell, so that when cut through the fourth cell it

will be the correct length to fit inside.

With your battery box dimensions in

hand, go down to your friendly neighborhood motorcycle shop and ask to

look at their 12 volt battery charts. These will show the dimensions of

each battery as well as the terminal types and locations. Keep in mind

that the new battery’s length is divided into 6 equal sized cells, you

should select one that when cut near the outer edge of the fourth cell

will render the 6 volt size you need. It needs to be cut near the outer

edge of the fourth cell to leave room for the new terminal connection on

the interconnecting link.

Be sure to tell your dealer not to

put acid in the battery. New batteries are usually shipped with a sealed

container of acid, make sure you get it along with the battery. While the

dealer may think he is doing you a service by filling and charging it,

in reality he will have ruined it for your purpose.

Now that you have your battery on the bench, look

at it carefully. One end should have a vent on it.

This

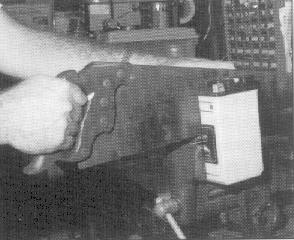

A hand saw cuts through the battery with ease

Voila’! You now have two batteries.

Inside you will see alternating layers of plates remaining in both halves.

Set aside the 2-1/4 cell part, you won't have much use for it. The lead

plates will be attached to the interconnecting link by small tabs. Take

a pair of wire cutters and carefully clip the lead plates away from the

link.

If you made the cut at the outer edge

of the fourth cell, there should be about 1/2" - 3/4" of

Looking at the freshly cut end, you

should see a ventway that runs the length of the battery across the top.

Your saw cut right through it. This ventway must be sealed at the cut end

to prevent acid from leaking out. Mix up a little epoxy and carefully fill

the opening. Use just enough to seal the end. Too much and it will seep

into the third cell, ruining it.

Now for the terminal leads. A two

conductor trailer wire connector is an easy way to make a quick disconnect.

The one I use is rated at 20 amps, as is the inline fuse holder. This doesn't

mean use a 20 amp fuse. Rather, use a fuse rated just a little over

your motorcycle’s maximum electrical load or generator's maximum rated

output, whichever is greater. For example my 101 Scout's Splitdorf generator

puts out a maximum of 5 1/4 amps, which is a little more than what the

headlight and taillight draw. A horn can draw anywhere from 2 to 5 amps

depending type, so be sure to take this into account. In this case I decided

to use a 7.5 amp fuse.

Solder a #10 ring terminal to one

end of the fuse holder lead. Feed one of the quick connect leads through

You may recall that when you first cut the battery

in two, there was some dark powder or sediment in the bottom of the battery

cell. This was residue from the insulating plates. As time goes on, the

plates will continue to deteriorate primarily due to vibration, leaving

this residue. Before adding the acid, remove all the caps and turn the

battery upside down and gently shake the residue out of all the cells.

This will help extend the life of your new battery.

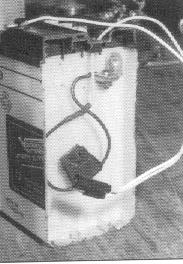

The completed 6 volt conversion

You are now ready to add the acid.

Take the battery outside to a safe location. Put on rubber gloves and safety

goggles. Follow the manufacturers instructions for filling the cells with

acid and charging.

For less than about $30.00 you have a new 6 volt

battery that should last several seasons if properly care for. Happy trails.